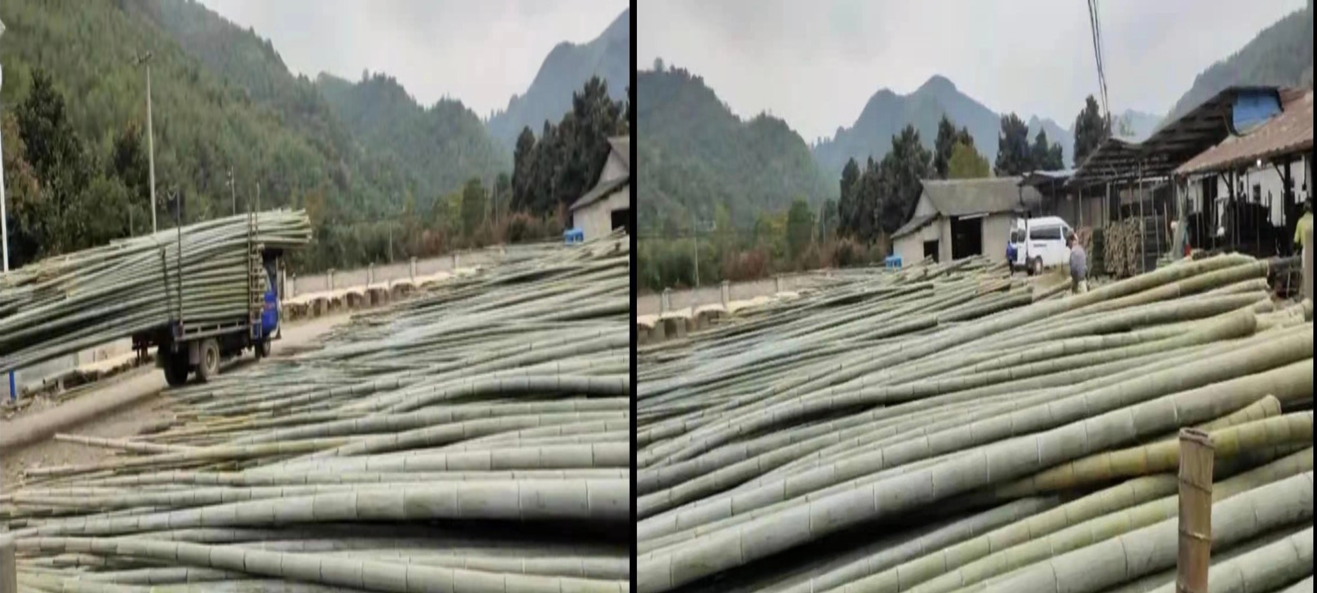

Bamboo Mat Production Process

1. Bamboo raw materials. Natural bamboo is purchased from provinces (Ninh Binh, Thanh Hoa, Hoa Binh, Lang Son, Cao Bang…) with age from 5-10 years.

2. Bamboo is purchased from organizations and individuals.

3. Workers sort bamboo into specific types to cut before transferring to the splitter.

4. Transfer the bamboo to the machine to split it into small bamboo strips of a certain size (called bamboo strips), (this step takes advantage of the broken bamboo strips and collects them to sell to civil paper factories, so that the natural raw materials are not thrown away and wasted).

5. Put the bamboo into the drying oven using the heat of the boiler at a certain temperature to dry the bamboo and prevent termites (the boiler uses charcoal as fuel to get heat without affecting the environment).

6. Workers classify the bamboo strips before putting them into the weaving machine.

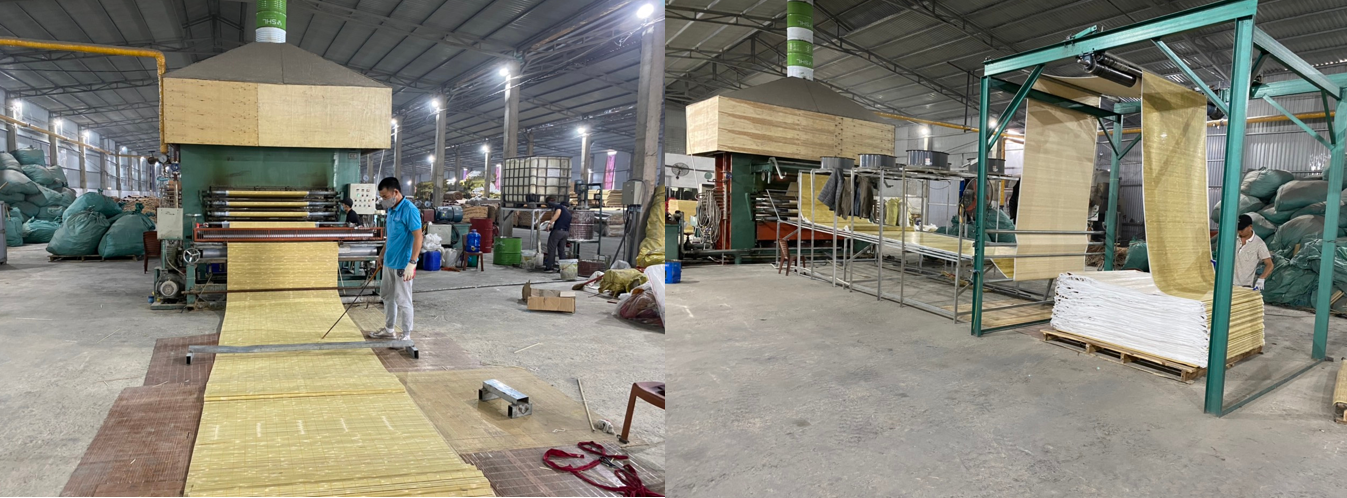

7. Transfer the bamboo strips to the weaving machine to make mats (combined with high strength thread to weave into mats of certain sizes) called mats.

8. Transfer the mat to the pressing line, using high temperature boiler heat combined with fabric, glue pressed onto the back of the mat to keep the mat durable (Environmentally friendly glue product).

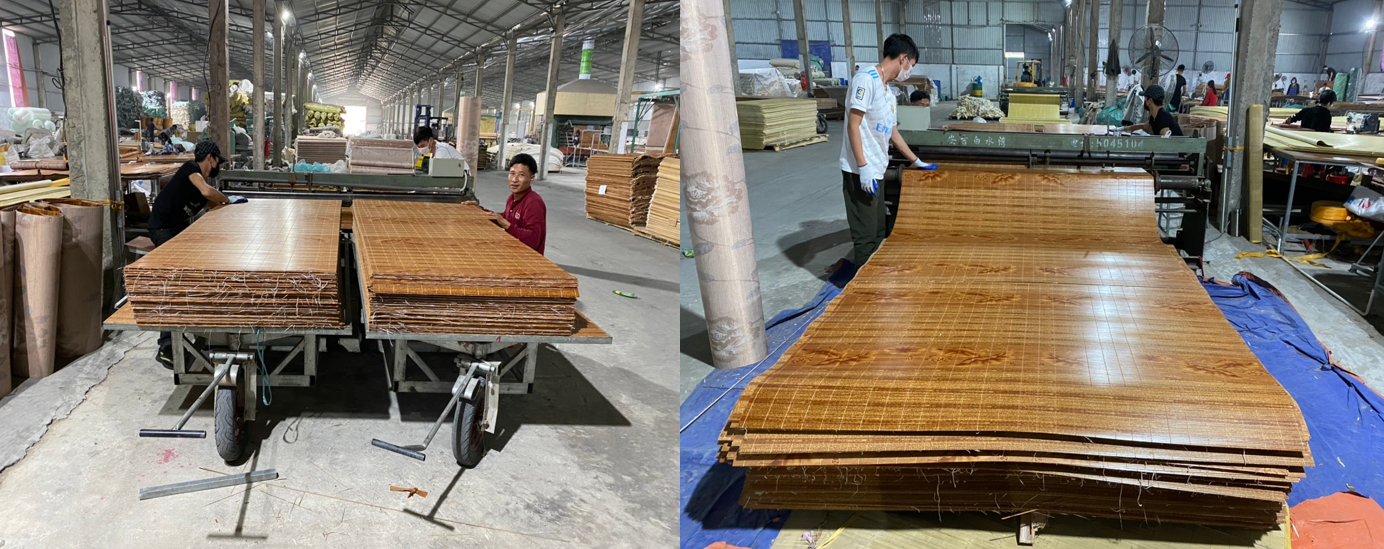

9. After pressing, some types of mats are transferred to print patterns (using a heat transfer machine combined with high-tech printing paper to print the mats).

10. Transfer to the cutting department to cut the mat into products of certain sizes.

11. Workers cutting corners and edges of mats:

12. Sew decorative borders around the edge of the mat.

13. Finishing and packaging stage:

14. Finished product warehouse

15. Delivery system to customers: